Contents

- 1 H2: What Is an Absolute Encoder and What Makes It Different?

- 2 How Does an Absolute Encoder Work Internally?

- 3 H2: What Are the Types of Absolute Encoders?

- 4 H2: Applications Where Absolute Encoders Are the Best Fit

- 5 H2: Benefits of Using Absolute Encoders in Automation

- 6 H2: How to Choose the Right Absolute Encoder

Hero Section (Bullet Summary at Top):

- What an absolute encoder is and how it tracks position: I’ll break down how these sensors give you an exact position reference — no guessing, no homing.

- How it works differently from incremental encoders: Unlike incremental types that only tell you movement steps, absolute encoders deliver a unique code for every position.

- When to use single-turn vs multi-turn absolute encoders: I’ll explain the trade-offs so you know which one fits your application best.

- Real-life applications in automation, robotics, and energy: From robotic arms to solar tracking systems, I’ve installed absolute encoders across industries.

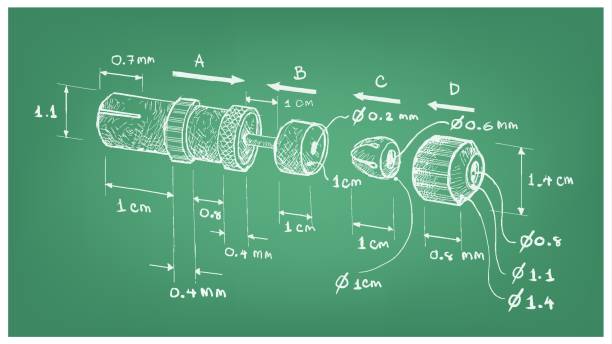

- Includes diagrams, signal explanation, and wiring notes: You’ll see clear visuals and practical wiring tips drawn from real-world setups.

H2: What Is an Absolute Encoder and What Makes It Different?

I’ve worked with absolute rotary encoders across everything from robotic pick-and-place systems to wind turbine blade positioning — and the one thing they all demand is reliable, unambiguous position data. That’s exactly what makes absolute encoders so valuable.

Unlike incremental encoders, which only tell you how much something has moved, absolute encoders tell you exactly where it is — even after a power loss. That’s because each position on the encoder corresponds to a unique digital code, not just a series of pulses. No need to return to a reference or “home” point after startup — the controller always knows where it is.

For example, on one AGV (automated guided vehicle) project, we had absolute rotary encoders on the wheel shafts. After a sudden power cut during a floor update, the system restarted and instantly resumed navigation without rehoming or manual intervention. That’s the kind of resilience and reliability automation demands.

So if your system can’t afford position loss — think multi-axis robotics, elevator controls, or high-precision metrology — absolute encoders are a no-brainer.

How Does an Absolute Encoder Work Internally?

Every time I spec or troubleshoot absolute rotary encoders, I’m reminded how much engineering is packed into these compact devices. Whether optical or magnetic, the principle is the same — assign a unique digital value to every possible shaft position.

Internally, absolute encoders use a sensor (optical or magnetic) to read a coded pattern on a disc. For optical types, the disc has concentric rings of transparent and opaque segments that represent binary or Gray code — a format designed so that only one bit changes between positions. This minimizes signal errors during transitions.

As the shaft rotates, a sensor array reads the light (or magnetic field) passing through these tracks. That raw data is then converted to digital position information using onboard logic or microcontrollers. With multi-turn encoders, a gear system or battery-less energy harvesting circuit counts full rotations as well — allowing them to track not just position within a turn, but over multiple turns.

Depending on the application, the encoder can output position data using various protocols:

- SSI (Synchronous Serial Interface) – simple, reliable for point-to-point links

- BiSS-C – a high-speed, open-source alternative with bidirectional capability

- CANopen or Profibus – for integration into industrial fieldbus networks

- EtherCAT – for high-performance motion control systems

Personally, I lean toward BiSS-C for its balance of speed and openness — I’ve used it in servo feedback loops where microsecond precision matters. But protocol choice often depends on what your PLC or drive accepts, so always check compatibility before purchasing.

H2: What Are the Types of Absolute Encoders?

In automation, not all position feedback needs are the same — and that’s why absolute rotary encoders come in two main types: single-turn and multi-turn. I’ve installed both in everything from compact robot joints to massive gantry systems, and choosing the right one always comes down to how far the system moves and whether position needs to be remembered over multiple rotations.

H3: Single-Turn Absolute Encoders

A single-turn absolute encoder provides a unique digital value for every position within one full 360° revolution of the shaft. That means even after a power cycle, the system knows exactly where the shaft is — as long as it hasn’t moved more than one turn during the outage.

I often use these in robotic arms, linear actuators, or sliding assemblies where movement is limited to a single rotation or less. They’re simpler, more compact, and cost-effective for applications that don’t require tracking multiple turns.

H3: Multi-Turn Absolute Encoders

Multi-turn encoders go a step further: they not only track position within a single revolution but also count how many full rotations have occurred. This is critical for applications with extended travel — like wind turbine blade pitch systems, large CNC axes, or elevators — where losing rotation count could mean serious misalignment.

Some models use mechanical gearing to track turns, while others use energy-harvesting or magnetic technology to store position electronically without needing a backup battery.

Personally, I always recommend multi-turn encoders for safety-critical or large-scale motion systems — especially when power loss is a possibility and precise recovery is essential.

H2: Applications Where Absolute Encoders Are the Best Fit

I’ve worked with a wide range of motion systems over the years, and when position must be known at all times — even after power loss — absolute rotary encoders are the go-to solution. Their ability to report an exact shaft angle or position immediately on power-up makes them essential in the following applications:

Industrial Robotics

In robotic arms, especially in multi-axis setups, absolute encoders ensure that each joint knows its precise angle at all times. There’s no need to move to a home position or run a startup routine — which saves time and reduces mechanical stress. I’ve installed them on both heavy-duty robotic arms and compact collaborative robots.

Elevators and Vertical Motion Systems

For vertical motion systems like elevators, absolute encoders provide exact positioning for safety and reliability. If power fails mid-travel, the system can restart without recalibration — critical in emergency scenarios.

Wind Turbines and Solar Tracking

In renewable energy systems, these encoders are essential. Wind turbine blade pitch control and nacelle orientation rely on multi-turn absolute encoders that track rotation count and angular position across hundreds of turns. In solar tracking systems, they help optimize panel alignment from dawn to dusk.

AGVs, Packaging Lines, and CNC Machines

Autonomous Guided Vehicles (AGVs) use absolute encoders to monitor wheel position and direction in real time — even after recharge or shutdown. In packaging systems and CNC machines, encoder feedback ensures precise alignment for cutting, filling, and sealing operations without wasting time on homing cycles.

H2: Benefits of Using Absolute Encoders in Automation

I’ve worked with both incremental and absolute encoders in industrial environments, and the benefits of using absolute encoders quickly become obvious when uptime, accuracy, and safety matter.

Position Always Known — Even After Power Loss

The biggest advantage? Absolute encoders never lose track of position, even if the system loses power or resets. This is critical in systems like robotic arms, conveyors, or AGVs, where restarting in the wrong position could damage equipment or create hazards.

No Need for Homing Sequences

With incremental encoders, you always need a homing routine at startup. That wastes time and introduces risk if sensors fail. Absolute encoders eliminate this — they report exact position the moment power is restored, which streamlines startup and reduces downtime.

Higher Reliability in Critical or Multi-Axis Systems

In multi-axis applications like CNCs or articulated robots, absolute rotary encoders give each axis an independent and consistent position reference. That’s essential for synchronized movement, especially where any misalignment could throw off the entire operation.

Ideal for Complex and Dynamic Environments

I’ve installed absolute encoders in wind turbines, vertical lifters, packaging lines — places where conditions change constantly or where physical homing is impractical. Because they maintain accuracy under vibration, motion, and environmental noise, they’re my go-to for demanding setups.

H2: How to Choose the Right Absolute Encoder

Choosing the right absolute rotary encoder (or linear, depending on the application) isn’t just about specs on paper — it’s about matching the sensor to your motion system’s real-world needs. Here’s how I walk through that process every time I spec one for a project:

Step 1: Define Motion — Rotary or Linear

Start with the basics: are you tracking rotational movement (like a servo motor shaft or a turntable) or linear motion (like a slider or gantry)? Most absolute encoders are rotary, but paired with racks or ballscrews, they can handle linear feedback too.

Step 2: Decide on Single-Turn vs Multi-Turn

If your application only needs position tracking within a single 360° rotation — like a robotic joint — a single-turn encoder is fine. But if you need to track multiple revolutions (say, the rotation of a wind turbine or large screw conveyor), go for a multi-turn encoder. It’ll remember position across turns, even if the machine is powered down.

Step 3: Choose Resolution (Bits)

This determines how fine your position data is. For example, a 12-bit encoder gives you 4,096 unique positions per turn. If you’re working on high-precision automation, CNC, or optical alignment, don’t skimp here — go higher resolution.

Step 4: Match Output Type

Always check what your PLC or controller accepts. I’ve worked with:

- SSI: Simple, reliable, widely used in industrial control.

- BiSS-C: Great for high-speed digital feedback.

- CANopen or PROFINET: When you need real-time networked communication.

Your encoder’s protocol must talk fluently with the rest of your system — or you’ll fight it every step of the way.

Step 5: Check IP Rating and Environmental Specs

If you’re installing the encoder in dusty, wet, or hot environments (like in packaging plants, outdoor equipment, or metal shops), IP67 or better is what I recommend. Also look at vibration resistance and operating temperature range. One cheap encoder exposed to coolant or metal chips can bring a whole system down.

Step 6: Consider Mounting and Wiring Constraints

Make sure the encoder fits physically. Check shaft size, flange type, or hollow shaft compatibility. Think about cable exits, connector types, and whether you have space for right-angle adapters. Bad mounting can create drift or even break the sensor.