Contents

Table of Contents

- Why Reliable Compressed Air Matters

- Common Sources of System Failure

- How to Spot Trouble Early

- Routine Maintenance Checklist

- Modern Monitoring Technologies

- Training Your Team for Consistency

- Final Thoughts

Why Reliable Compressed Air Matters

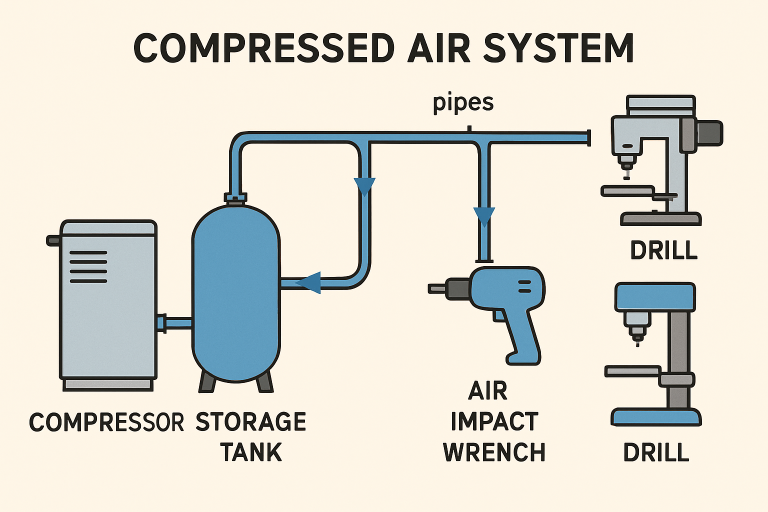

Compressed air powers essential applications in manufacturing, food processing, pharmaceutical plants, and many other industries. It’s often called the “fourth utility” after water, electricity, and natural gas for a good reason—an unexpected compressed air failure can force an entire facility to a standstill, leading to costly production interruptions and missed deadlines. The reliability of your compressed air system is as critical as the quality of any other core utility in your facility. Integrating robust components like ANSI pumps can support consistent air stream delivery and overall operational dependability.

Reliable compressed air systems not only uphold productivity but also directly impact energy consumption and maintenance overhead. Facilities experience significant cost savings by maintaining uptime and minimizing inefficiencies. According to Automation World, well-maintained systems drastically reduce energy waste and boost productivity. Investing in system reliability, therefore, becomes a strategic decision—a safeguard for efficient operations and sustainable performance.

Common Sources of System Failure

Like all complex industrial systems, compressed air setups are vulnerable to a handful of common issues. Air leaks are a major culprit, accounting for 20-30% of a compressed air system’s total output loss. Aging, worn parts, loose fittings, and inadequate routine inspections frequently cause these leaks. Other leading causes of system failure include overheating from insufficient cooling, lack of regular oil changes, dirt or moisture in lines, and improper installation of system components. The age of your equipment also matters—outdated machinery is more likely to break down unexpectedly, highlighting the importance of timely upgrades and replacements.

How to Spot Trouble Early

Early identification of issues is key to preventing major failures. Facilities should stay alert for indicators like sudden drops in air pressure, equipment making unusual noises, and unexplained increases in energy bills. Smaller symptoms—such as inconsistent tool performance or visible condensation around piping—can signal deeper problems within the air distribution network. Operators should also monitor automated readings from system sensors, if available, to catch anomalies before they escalate. Prompt investigation ensures that minor concerns don’t balloon into full-scale breakdowns.

Routine Maintenance Checklist

- Check and change air filters regularly to ensure clean air and system efficiency.

- Inspect for leaks in piping, hoses, and connections. Address leaks as soon as they are found.

- Monitor lubricant levels and perform regular air compressor maintenance, changing oil according to manufacturer recommendations to protect compressors.

- Clean heat exchangers and cooling surfaces to avoid overheating issues.

- Schedule annual system-wide audits to catch inconsistencies that might not be obvious from daily checks.

The U.S. Department of Energy reports that up to 50% of compressed air is lost through leaks and poor maintenance. Implementing this checklist helps prevent unnecessary downtime and improves overall equipment life.

Modern Monitoring Technologies

Monitoring technologies have transformed reliability practices in recent years. Wireless sensors, IoT-based smart devices, and real-time analytic platforms now offer continuous system insight, allowing operators to receive instant alerts about pressure drops, excessive vibration, or impending component failure. These systems can automatically log data and support trend analysis, making it easier to anticipate maintenance needs before failures occur.

The Role of Predictive Analytics and Automation

Advanced analytics integrate with programmable logic controllers (PLCs) and building management systems to help maintenance professionals track energy usage and system irregularities and predict when a component may fail. These advances lead to a proactive reliability culture where issues are addressed before they result in unplanned interruptions.

Training Your Team for Consistency

The best technology and components are only as effective as the team maintaining them. Investing in staff training for daily routines, emergency response, and system troubleshooting is critical. Maintenance teams with up-to-date knowledge of the latest compressed air system care practices have consistently demonstrated fewer unexpected outages and smoother production schedules.

Empowering Through Continuous Learning

Regular workshops, cross-training, and working closely with OEMs and suppliers help build an in-house maintenance team equipped to quickly identify, report, and deal with anomalies. Developing clear procedures and instructions ensures expertise is maintained even when staff changes occur.

Final Thoughts

Reliable compressed air systems are the backbone of efficient industrial operations. By combining well-maintained equipment, proactive monitoring, and a trained maintenance team, facilities can minimize downtime, reduce energy waste, and extend the lifespan of critical components. Investing in modern technologies, following routine maintenance protocols, and fostering continuous learning among staff ensures consistent performance and long-term operational resilience. Prioritizing system reliability ultimately safeguards productivity, lowers costs, and supports sustainable, safe, and efficient facility management.