Coastal development presents unique challenges that call for innovative solutions. As coastal regions face the threats of erosion, rising sea levels, and extreme weather events, the engineering sector must adapt with robust and resilient infrastructure. This is where the pivotal role of engineered casting solutions for coastal projects comes into play. These solutions are essential in constructing durable structures that can withstand the harsh maritime environment while promoting sustainable development.

Contents

The Significance of Engineered Casting in Coastal Engineering

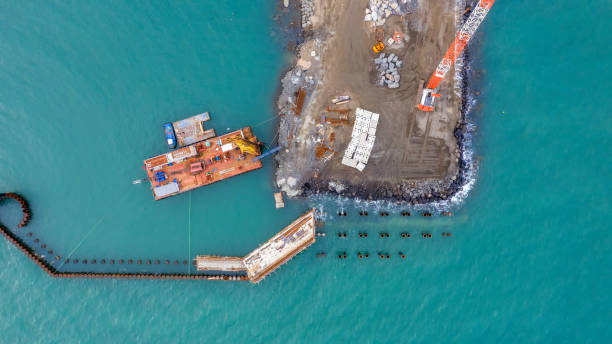

Engineered casting solutions provide the strength, precision, and versatility needed in coastal constructions such as sea walls, breakwaters, and jetties. Through meticulous design and manufacturing, these castings ensure that structures have the longevity and resistance essential for coastal defence. By employing these cutting-edge technologies, developers are able to minimise maintenance costs and maximise reliability in coastal development.

Moreover, the integration of engineered casting into coastal engineering is not just about withstanding natural forces; it is also about ecological consideration. Modern casting solutions are capable of integrating with natural environments, thereby promoting biodiversity and reducing the ecological footprint of construction activity.

FC Casting Solutions: Leading the Way in Coastal Engineering

At the forefront of providing state-of-the-art casting solutions is FC Casting Solutions. With a reputation for excellence in casting technology, the company is equipped to handle the complex requirements of coastal development projects. Their expertise spans across the consultation, design, and manufacturing stages, ensuring a holistic approach to fulfilling the needs of modern coastal infrastructure.

Custom Industrial Metal Castings: A Core Competency

A key aspect of FC Casting Solutions’ service offering is their custom industrial metal castings foundry. This facility is capable of producing high-quality castings tailored to the stringent demands of coastal engineering. With a focus on precision and adaptability, the foundry can produce a wide array of custom components that are pivotal in building resilient coastal structures.

The Advantages of Engineered Casting Solutions

Engineered casting solutions provide numerous benefits to coastal development projects. Firstly, they offer increased durability against the corrosive marine atmosphere, an essential consideration for any structure exposed to saltwater. Secondly, the customisability of these solutions means that each component can be optimised for specific structural needs, enhancing the overall integrity of the construction. Lastly, the streamlined production process of engineered castings results in time and cost-efficiency, making it a financially viable option for developers.

Implementing Engineered Casting in Coastal Projects

The practical application of engineered casting solutions is broad and varied within coastal engineering. Structures like groynes and revetments become more efficient in their coastal protection roles when reinforced with precision castings. In the context of port and harbour development, engineered castings are crucial for fender systems, anchoring mechanisms, and load-bearing components subjected to heavy maritime traffic.

Furthermore, engineered casting contributes to renewable energy projects along coastlines, such as tidal and wave energy converters. These innovative applications demonstrate the versatility and essential role of engineered castings in not only providing protection but also in supporting the sustainable harnessing of natural resources.

Challenges and Considerations in Coastal Casting

Although engineered casting solutions offer outstanding benefits, there are challenges to navigate in coastal environments. It is imperative to select appropriate materials that resist wear and tear from sea water. Engineers and foundries must collaborate closely to ensure that the casting processes and material choices are apt for the precise conditions of each project. This requires a comprehensive understanding of site-specific factors such as climate, marine life, and hydrodynamics.

In addition, considering the potential environmental impacts of coastal projects is crucial. Engineered castings must be designed with sustainability in mind, ensuring that they do not disrupt marine ecosystems while providing long-lasting solutions for coastal development.

The Future of Coastal Development with Engineered Casting

The future of coastal development looks bright with the continuous innovation in engineered casting solutions. With advancements in materials science and manufacturing techniques, the potential for creating more efficient, sustainable, and stronger coastal structures is vast. FC Casting Solutions continues to pioneer these developments, pushing the boundaries of what is possible in coastal engineering.

As the demand for sustainable infrastructure grows, the adoption of engineered casting in coastal projects is set to increase. With its blend of customisability, durability, and precision, engineered casting represents a vital component in the protection and enhancement of our coastal landscapes.

In conclusion, engineered casting solutions offer an indispensable foundation for coastal development. Companies like FC Casting Solutions lead the charge in providing the advanced, custom-fit solutions necessary for the challenges of modern coastal engineering. As these technologies continue to evolve, coastal communities can look forward to stronger and more environmentally harmonious infrastructure to safeguard their future.

With the dedication of industry experts and the application of engineered casting solutions, the coastal regions can achieve the balance between development and preservation that is crucial for the wellbeing of both human populations and the marine environment. It is through these innovations that we can truly harness the power of engineering to support sustainable coastal development for generations to come.